Automated and effective

Shrimp processing line

Carsoe manufactures shrimp lines onboard both large freezing vessels and fresh fish vessels in many different sizes.

A Carsoe shrimp processing system has a high degree of automation and is designed to withstand tough weather conditions and long-time use.

Our processing line for cold water shrimp is designed for gentle treatment of the catch. It preserves the quality of the shrimp and ensures a high capacity production line, with reduced manual labour and increased productivity.

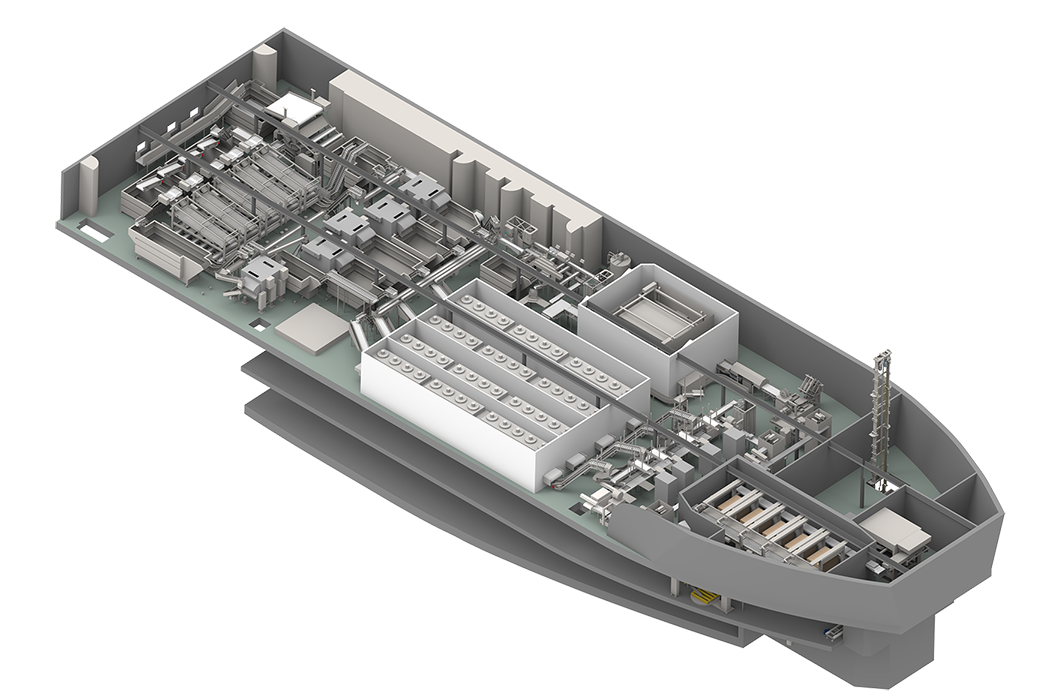

Freezing vessel

Shrimp processing equipment for freezing vessels

Carsoe is your market leading partner from start to finish for your shrimp factory. We ensure that the processing capacity and finished product are strictly in accordance with your requirements.

A freezing vessel is a big investment and we take pride in completing the project with a successful installation and test of your equipment followed up by training your employees in operating and maintaining the equipment.

Carsoe manufactures shrimp lines for all types of freezing vessels in sizes ranging from approx. 50 meters in length and upward.

Onboard shrimp factory

Turnkey Seafood Processing Solution for freezing vessels

Take a closer look at how our shrimp processing solutions work onboard freezing vessels.

3 Key Features

Freezing solutions

As part of the complete shrimp processing line, we also include autofreezers to automate the processes onboard and increase your production rate.

Sorting and palletizing

Get clean pallets and store them safely with integrated hotels and palletizing. We design, build and deliver the complete package.

Elevators for easy handling

Easily transport your catch to the cargo hold with a minimum of manual handling and ensure effective offloading with onboard elevators.

At Carsoe, we manufacture all types of shrimp processing lines

References for freezing vessels

Fresh fish vessel

Shrimp processing lines for fresh fish vessels

Carsoe is the leading global provider of seafood processing equipment for fresh fish vessels. We manufacture shrimp factories for many different sizes of fresh fish vessels ranging from approx. 15 meters in length and upward.

With our market-leading technology, we help customers streamline onboard shrimp lines making them more efficient and automated while enhancing the quality of the catch.

The layout of your shrimp processing line fully depends upon your individual needs. Every factory is tailormade to make it fit 100% in accordance with your vessel. Your shrimp factory can be designed with a high degree of automation to provide a full overview of the total load. It all comes down to your demands.

Carsoe's comprehensive product portfolio includes machines for sorting, cooking, weighing, freezing, and packing, simplifying the process of creating an efficient and effective line for processing shrimp.

Onboard shrimp lines

Seafood Processing Solution for fresh fish vessels

See how some of our many shrimp processing solutions work onboard fresh fish vessels.

Let Carsoe manufacture your next shrimp processing line

References for fresh fish vessels

Industry-leading solutions

Reasons to opt for Carsoe's industry-leading solutions

When considering Carsoe products for your commercial shrimp processing needs, several key factors distinguish us as the preferred choice in the industry. Our extensive experience in creating advanced onboard processing plants for seafood, numerous satisfied clients, and extensive expertise speak to our unwavering commitment to excellence.

We continually invest in research and development, fostering the advancement of new technologies tailored for the next generation of trawlers. Our unique understanding of diverse production systems and processes positions us as an invaluable partner in optimising your operations.

Carsoe also stands as a reliable provider of complete land-based processing lines for farmed warm water shrimp, catering to the growing global market with worldwide delivery. Warm water shrimps, known for their delicate flavour and tender texture, flourish in tropical and subtropical regions, making them a popular seafood choice.

All of our machines for processing shrimp and other seafood are designed with a focus on superior quality, durability, and low maintenance requirements. We are confident in our ability to provide in-depth expertise in shrimp processing plant layout design, ensuring optimal efficiency and productivity for our clients.

We are here to help with your next shrimp processing factory

Contact Carsoe today

Products for shrimp processing

Browse through the various products part of our shrimp processing line.

Combining our machines will allow you to design an efficient cold-water shrimp processing plant. This is where Carsoe's expertise and year-long knowledge comes in.

We look forward to hearing from you

Questions or need advice on seafood processing?

Fill in the form and let us contact you.

Shrimp processing system

The key benefits of utilising an advanced, automated shrimp processing system

Partnering with us allows you to establish a cutting-edge, automated onboard processing line tailored for cold water shrimp. In addition to our robust solutions for sorting, cooking, weighing, freezing, and packing, Carsoe's innovative approach includes state-of-the-art plate freezing technology. This technology ensures the optimal preservation of seafood quality, enhancing the efficiency of your shrimp processing operation. The primary advantages of implementing a sophisticated and automated shrimp processing system include:

- Preserved product freshness: Advanced freezing techniques guarantee the preservation of nutritional content, texture, and flavour for an outstanding final product.

- Prolonged time at sea: Efficient onboard shrimp processing plant allows vessels to spend more time fishing, increasing productivity and yield.

- Eco-friendly energy usage: Productive systems are designed to reduce environmental impact and energy consumption for sustainable operations.

- Waste minimization: Our cutting-edge technology contributes to minimising waste and promoting responsible resource management.

- Maximising profits: By decreasing costs and increasing output, our streamlined processes empower shrimp processors to optimise their earnings.

Shrimp processing plant

How to start a shrimp processing plant?

Creation of an effective and efficient onboard shrimp processing procedure may appear challenging, but with the right guidance and equipment, it is an achievable undertaking.

To begin, consider implementing a Carsoe by-catch separator, designed to efficiently separate small fish from shrimp automatically. Next, integrate our shrimp grading machine, crafted to gently and accurately grade shrimp by size.

As you continue to build your processing line, our high-capacity automatic batch cooker delivers optimal value by ensuring perfectly cooked shrimp while maintaining a stable temperature with minimal variation. Notably, the shrimp are cooled and prepared for freezing as they exit the cooker.

For rapid freezing of shrimp and other delicate products, our IQF tunnel freezer is the perfect solution, engineered to smoothly integrate with existing processing lines as part of an automated workflow.

The automatic freezing section can be coupled with a fully automated packaging line, allowing for streamlined master box integration.

Once the shrimp are frozen and packaged, they are temporarily housed in a hotel, where they are sorted and readied for onboard palletizing.

Our Carsoe hotels provide effective product organisation and storage prior to entering the palletizing section, which is equipped with an integrated elevator, ensuring a fully automated process until the products are retrieved by a forklift in the cargo hold.

The elevators facilitate quick and efficient cargo transportation between decks, minimising manpower demands and optimising onboard space utilisation.

By leveraging our expertise and advanced equipment, you can confidently establish a complete and efficient onboard shrimp processing plant that meets your unique needs and requirements.

An experienced partner

An experienced partner within processing shrimps

Efficient shrimp processing procedure is essential for long-term success in the seafood industry. At Carsoe, we understand the importance of both efficiency and quality when it comes to choosing shrimp onboard processing options.

Our experienced team evaluates the specific needs of each shrimp processing facility, and we provide a meticulous installation process to ensure optimal performance according to the individual requirements of each customer.

With our comprehensive training program after commissioning, you'll be fully prepared to achieve reliable production with minimal ongoing maintenance requirements. Our solutions allow you to focus on what matters most: producing high-quality shrimp products and succeeding in today's competitive market.

Carsoe is committed to providing efficient and effective solutions for shrimp processing. Contact us today to learn more about how our commercial shrimp processing solutions can help you achieve success in the seafood industry.

A world-leading company within shrimp and seafood processing

Carsoe is a world-leading company in the seafood processing industry, dedicated to providing exceptional quality of seafood processing facilities tailored to the unique needs of our clients. Our focus on developing high-quality shrimp processing solutions has led us to develop complex systems that streamline the processing of shrimps and other types of seafood.

Our team draws on years of experience and strong relationships with our clients worldwide to develop the best customised seafood processing layouts. By listening to our customers' needs and experiences, we create solutions that are perfectly adapted to their specific requirements. We understand the importance of delivering a reliable and efficient shrimp processing system to help our clients achieve success in the competitive seafood industry.

Our prowess extends beyond shrimp to include specialized solutions for crab processing. Dive deeper into our innovative crab processing technology and how it can elevate your seafood processing capabilities.

All of our machines for shrimp processing, fish processing and other seafood are designed with a focus on superior quality, durability, and low maintenance requirements. We are confident in our ability to provide in-depth expertise in shrimp processing plant layout design, ensuring optimal efficiency and productivity for our clients.

Read all about our company here.

We are ready to help and guide you to choose the right processing option

When it comes to processing shrimp, we understand that choosing the right equipment can be a critical decision.

Our team of experienced professionals can provide you with tailored advice, helping to find the perfect shrimp processing system for your unique requirements. Whether you need a complete processing line, a specific machine or wish to know more about our landbased processing equipment, we are here to guide you.

Don't hesitate to get in touch with us today and discover how our knowledgeable specialists can assist you in achieving your goals.

FAQ

What are the unique features of Carsoe's shrimp processing lines for freezing vessels?

Carsoe's shrimp processing lines for freezing vessels are designed for durability, high automation, and efficient operation in harsh weather conditions. They offer comprehensive solutions from the start to the finish of your shrimp factory, including successful installation, testing, and employee training. These lines are suitable for vessels approximately 50 meters in length and upwards.

What are the key features of Carsoe's shrimp processing equipment?

Carsoe offers three key features in their shrimp processing equipment:

- innovative freezing solutions

- integrated sorting and palletizing systems

- efficient elevators for easy handling

These features are integral to automating processes, ensuring clean and safe storage, and facilitating effective catch transportation and offloading.

Can Carsoe's shrimp processing lines be customized for different vessel sizes?

Yes, Carsoe provides tailor-made shrimp processing lines for both fresh fish vessels and freezing vessels. These lines can be customized for a variety of vessel sizes, starting from approximately 15 meters in length, with a high degree of automation and layout design tailored to individual needs and demands.